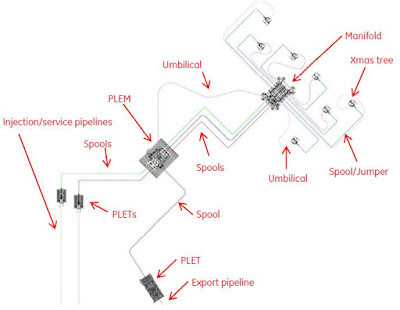

A typical subsea oil and gas field consists mainly of Xmas trees, manifolds, termination

units and pipelines. A termination unit can be called a “PLEM” or a “PLET.” These units are connection points between two or several pipelines. The Pipeline End Termination (PLET) comprises a single pipeline connection only, while the Pipeline End Manifold (PLEM) is supporting two or more pipeline connections.

|

Pipeline end manifold (PLEM)

Source: https://sal-heavylift.com/uploads/tx_salext/gallery/plem06_01.jpg |

|

Pipeline end termination (PLET)

Source: http://www.marinewellcontainment.com/wp-content/uploads/2015/01/PLET.jpg |

- Midline connection

- Horizontal connection

- Pull-in and connect method

- Subsea connection

|

PLET and PLEM in subsea field layout

Source: http://brage.bibsys.no/xmlui/bitstream/handle/11250/183156/Thorsen,%20Steinar.pdf?sequence=1 |

The PLET is generally installed subsea pre-attached to the pipeline end. The assembly consisting of the substructure and the pipeline end, is called “PipeLine End Termination” or “PLET”. If the size of the pipeline or the substructure is large, it becomes not suitable to install them simultaneously as a completed PLET assembly. An “Open PLET” is a PLET assembly which requires to be assembled on the seabed after a separate installation of the pipeline and the substructure. This is due to the size and weight of the pipeline and or the substructure.

|

Open PLET in subsea field configurations

Source: http://brage.bibsys.no/xmlui/bitstream/handle/11250/183156/Thorsen,%20Steinar.pdf?sequence=1 |

|

Open PLET components

Source: https://sal-heavylift.com/uploads/tx_salext/gallery/plem06_01.jpg |

Mud-mat: Prevents the Open PLET from sinking into the mud/seabed. The perforation ensures water current through the structure. This gives better maneuverability during installation.

Porch: The Porch on the Open PLET is referred to as “Porch open” due to the ability to engage and disengage with the pipeline end termination after subsea installation. The Porch on the Open PLET can be regarded to consist of the two alignment structures, Porch = MAS+RAS. The RAS is required, because the clamping of the end termination to the Porch open is not as good as for a regular Porch (for the Porch open, the MAS alone provides insufficient pipeline clamping capability to deal with applied moment loads).

Main Alignment Structure (MAS): The structure has interfaces towards the pipeline end termination for guiding purpose and for clamping. It provides locking pins for locking of the pipeline end termination in axial direction.

Rear Alignment Structure (RAS): The structure has interfaces towards the pipeline end termination for guiding purpose and for clamping. The RAS provides a guide-yoke which facilitates guiding, alignment and locking of the pipeline end termination.

Alignment bumpers: The bumpers are used for alignment of the Open PLET towards the pipeline end termination during subsea installation. One of the bumpers provides a marking system to facilitate positioning of the Open PLET in axial direction.

Pad-eyes: One set of pad-eyes is used for the installation of Open PLET from vessel to seabed. The other set of pad-eyes is used for a pull operation at seabed when repositioning the Open PLET in axial direction.

Source:

http://brage.bibsys.no/xmlui/bitstream/handle/11250/183156/Thorsen,%20Steinar.pdf?sequence=1

Wonderful

ReplyDeleteIs it possible to show what is the piping & framing that can be inserted in the pre-installed "porch open" concept?

ReplyDeletevery useful for newbie

ReplyDeletePipeline Ending Manifold (Plem)/Plet >>>>> Download Now

ReplyDelete>>>>> Download Full

Pipeline Ending Manifold (Plem)/Plet >>>>> Download LINK

>>>>> Download Now

Pipeline Ending Manifold (Plem)/Plet >>>>> Download Full

>>>>> Download LINK

These PLET/PLEM/ILT are known as ILS (In-Line Structure). We have designed multiple PLETs, While designing PLET lot of Design review meetings are conducted to ensure everything is aligned as per the codes and standards. In addition to that we maintain the very high safety of factor and keeping the quality at the top.

ReplyDelete#Subsea means we can say no compromise on quality.